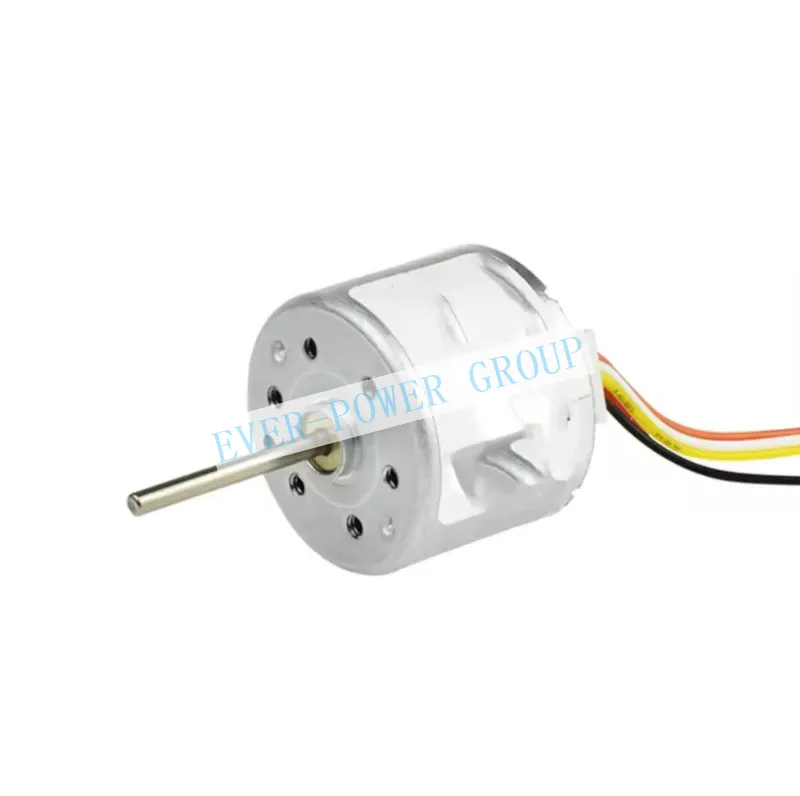

Encoder DC Motor

HIGH QUALITY PRECISE MANUFACTURER

&SUPPLIER

Professional made

We are a well-known company specializing in the production and sales of high-quality Encoder DC Motors. With deep industry experience and innovative technology, we are committed to providing customers with excellent motor solutions.

Our encoder DC motor combines the high-precision measurement of the encoder with the stable performance of the DC motor to achieve precise control of the motor’s motion state. Whether it is speed, position or direction, our products can accurately meet your needs and ensure efficient and stable operation of the equipment.

Our company focuses on product quality and technological innovation. Our encoder DC motors enjoy a high reputation in the market and are widely used in many fields such as robots, automation equipment, and CNC machine tools. We insist on being customer-centric, providing personalized services and support to help customers solve practical application problems.

Choosing our company means choosing quality and trust. We will continue to uphold the concepts of professionalism, innovation and service and work with you to create a better future.

Advantages of encoder DC motors compared with other motors

| Feature | Encoder DC Motors | Standard DC Motors | Stepper Motors |

|---|---|---|---|

| Feedback | Provide precise feedback on position and speed | No feedback unless additional sensors are used | Provide feedback based on steps, but generally lack real-time speed and position feedback |

| Control Precision | High precision due to feedback allowing for exact positioning and speed control | Less precision, control based on voltage and current without feedback | Moderate precision, dependent on step size and prone to errors without feedback |

| Complexity | More complex due to integrated encoder, but offers more control capabilities | Simpler, fewer components, less control capabilities | Relatively simple but requires careful control to manage step errors |

| Cost | Generally higher due to the addition of an encoder | Lower cost, fewer components | Costs vary, generally lower than encoder DC motors but can increase with complexity |

| Efficiency | High efficiency with precise control reducing wastage | Efficiency varies, less optimal without feedback | High efficiency in controlled environments but can waste energy through heat |

| Torque | Consistent torque across a range of speeds, enhanced by precise control | Torque varies with speed and load, less predictable | High starting torque but can decrease with speed |

| Speed Range | Wide speed range with control across all speeds | Broad speed range but less control at lower speeds | Limited high-speed performance, best at low to medium speeds |

| Application Suitability | Ideal for applications requiring precise control, such as robotics and automated systems | Suitable for general-purpose applications where precise control is less critical | Best for applications requiring rotational or partial rotational movement where precision in steps is crucial |

| Maintenance | Requires more maintenance due to complexity of encoder | Lower maintenance due to fewer components | Moderate maintenance, especially in systems where step accuracy is critical |

| Response Time | Fast response due to real-time feedback | Response time can be fast but less precise without feedback | Slower response due to nature of stepping, potential for resonance issues |

What is an encoder DC motor?

An encoder DC motor is a DC motor with an integrated encoder, which incorporates the encoder’s function directly into the motor’s design. An encoder is a device that can measure and provide feedback on a motor’s rotational position, speed, or direction. In contrast, a DC motor is a device that converts DC electrical energy into mechanical energy.

Encoder DC motors can monitor the rotation status of the motor in real-time through the built-in encoder and feed this information back to the control system. Based on the feedback data from the encoder, the control system can accurately control the motor, including adjusting the motor’s speed, rotation direction, and positioning accuracy.

Encoder DC motors are used in many applications, especially where precise control of motor position and speed is required. They play an important role in fields such as robotics, automation equipment, CNC machine tools, and power tools.

Design of encoder DC motor drive system

First, we need to clarify the specific specifications and requirements of the encoder DC motor, including the motor’s rated voltage, rated current, rated power, speed range, encoder type, accuracy, etc. These parameters will directly determine the design and performance of the drive system.

Next, we must design the power circuit to provide stable and reliable power to the motor. This usually includes rectifier circuits, filter circuits, voltage regulation circuits, etc., to ensure the motor can obtain the required voltage and current under different operating conditions.

In the drive circuit design, we need to select appropriate power devices and drive strategies based on the motor’s control method and performance requirements. For example, for applications that require precise control of speed and position, we can use PWM (pulse width modulation) technology to achieve accurate control of the motor current by adjusting the switching duty cycle of the power device.

At the same time, the processing of encoder signals is also a key part of the drive system design. The encoder’s signal output needs to be decoded and filtered to extract information such as the motor’s speed and position. This information will be used as a feedback signal to achieve closed-loop motor control.

Application areas of encoder DC motors

Robotics

In industrial and service robots, encoder DC motors are used to provide precise motion control, enabling robots to perform delicate operations and complex automation tasks.

Medical Equipment

In a variety of medical instruments and equipment, such as surgical assist robots, diagnostic equipment, and therapeutic equipment, encoder DC motors are used to ensure precise and reliable operation.

Motion control systems

In a variety of applications that require precise speed and position control, such as CNC machine tools, laser cutters and other precision machining equipment.

Automation equipment

In automated production lines, encoder DC motors are used to control the precise movement of machines, such as automatic assembly machines, sorting systems, and packaging machinery.

Consumer electronics

In camera lens focusing systems, printers, and other precision equipment, encoder DC motors are used to achieve high-precision control.

Aerospace

In the aerospace industry, encoder DC motors are used to control a variety of aircraft systems, including navigation and driver assistance systems.

Advantages of Encoder DC Motor

High Precision Control

Encoders allow for precise control of the motor’s position, speed, and acceleration. This is essential in applications like robotics, CNC machines, and automated assembly lines where exact movements are crucial.

Enhanced Feedback Loop

The feedback provided by the encoder ensures that the motor can adjust in real-time to changes or discrepancies between the expected and actual positions or speeds. This feedback loop is critical for closed-loop control systems, enhancing reliability and performance.

Improved Efficiency

With accurate control over speed and position, Encoder DC Motors operate more efficiently by reducing waste and minimizing the energy spent on unnecessary movements or corrections.

Main types of encoder DC motors

The main types of encoder DC motors can be divided according to the different forms and functions of the encoder. Here are some of the main types:

1. Incremental encoder DC motor: The incremental encoder is an optical encoder that determines the position angle based on incremental calculation. It converts the displacement into a periodic electrical signal, and then converts the electrical signal into a counting pulse. The number of pulses indicates the magnitude of the displacement. Each position is completely unique, and the control system processes these pulses for precise positioning or rotational speed measurement.

2. Absolute encoder DC motor: Absolute encoders provide a single code for each position and are divided into single-turn encoders and multi-turn absolute encoders. Their small size allows for simpler integration. Each position of the encoder corresponds to a certain digital code, so its indication is only related to the starting and ending positions of the measurement, and has nothing to do with the intermediate process of the measurement. The absolute encoder outputs the position in the form of a bit sequence, which is transmitted in the controller frequency via a suitable protocol. This kind of motor is usually used in situations where the current position needs to be known clearly, such as the application of brushless DC motors in specific industries such as medical machinery.

Blog

Why choose our company?

1. High-quality products: Our company is committed to providing the highest-quality Encoder DC Motor. Our products are precision-engineered and manufactured using advanced materials to ensure durability, reliability, and consistent performance.

2. Comprehensive Service: We pride ourselves on providing excellent customer service. Our professional team is ready to answer your questions, provide technical support, and provide solutions tailored to your needs.

3. Competitive Prices: Our company offers competitive prices without compromising on quality. We believe in creating value for our customers and work hard to ensure our products fit every budget.

4. Excellent after-sales support: We know that a product is only as good as the support you receive after purchasing it. Our company provides comprehensive after-sales services, including timely repair, replacement, and maintenance, ensuring that your Encoder DC Motor is in optimal condition for a longer period of time.

5. Rich product range: Our company provides a variety of Encoder DC Motor shafts to meet different applications and requirements. We can provide you with the right product.